Bussiness

Business creating onion skin packaging to reduce waste

BBC

BBCA start-up business in Oban is developing eco-friendly packaging made from onion skins in a bid to cut waste and reduce emissions.

Renuka Ramanujam, CEO of HUID (the Dutch word for skin) is a former textiles student who first used onion skins as a source of clothing dye.

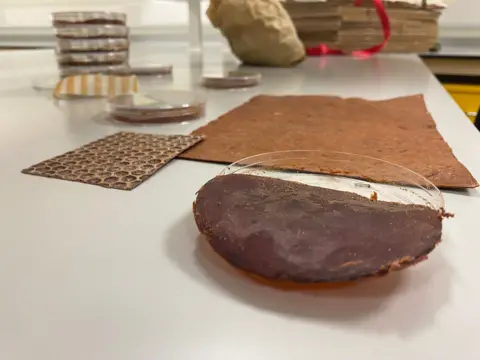

The 30-year-old’s company sources waste peel from farmers and agricultural businesses and is developing a cardboard-like material, as well as an alternative to flexible film.

It is supported by industry-led body, the National Manufacturing Institute Scotland.

Onion skins have anti-microbial properties, meaning the packaging could help extend the shelf life of perishable foods.

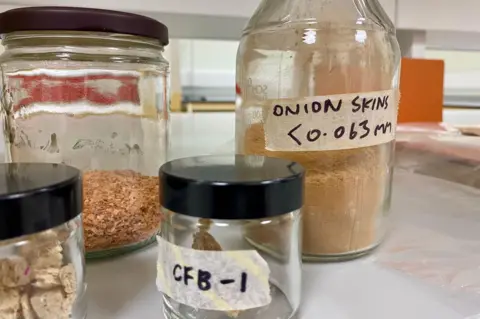

Producing the eco-packaging involves extracting high-quality cellulose from outer onion skins and combining it with a biopolymer blend.

Polymers are very long chain molecules made from small repeating units – biopolymers are polymers made from natural sources like proteins, carbohydrates, and fats.

HUID is attempting to reduce waste as UK households throw away an estimated 90 billion pieces of plastic packaging annually.

“I started experimenting with the material on my bedroom floor,” Ms Ramanujam said.

“Plastic leaches chemicals into food when it’s heated. I wanted to find a solution from something with no value.

“Imagine any meal you have – there’s bound to be some onion in there. Onions are a global staple for cuisines. They’re everywhere, so their waste is everywhere too.”

Originally from India, but Dutch by nationality, Ms Ramanujam moved from London to Oban in 2021 after an invite from a friend.

“Everyone I tried to get in touch with in London didn’t respond,” she said. “I’ve stayed in Oban because the community is so powerful.”

She said work had been accelerating since she recruited chief scientific officer Marie Rapin.

Ms Rapin is working on a flexible film which could replace plastic bags for food items such as spinach.

“At the moment, the prototypes are translucent and a little bit thicker than we want,” she said.

“We’re also looking at making egg-carton-like products.”

The pair hope to launch their first product next year – paper made entirely from onion skins.

Ms Ramanujam also hopes to replace cardboard and paper packaging.

“Trees are super important to the environment, because of the animals they home and the carbon they hold,” she said. “Onions don’t have that responsibility.

“Our material would save trees.”

Ms Ramanujam believes packaging is here to stay.

“Whether that’s protection or cost, we’re always going to need it,” she said.

“We want to make sure it’s done in the best way possible.”

A spokesperson for the National Manufacturing Institute Scotland said it championed sustainable solutions and supported small and medium-sized businesses through access to expertise and equipment they may not have.